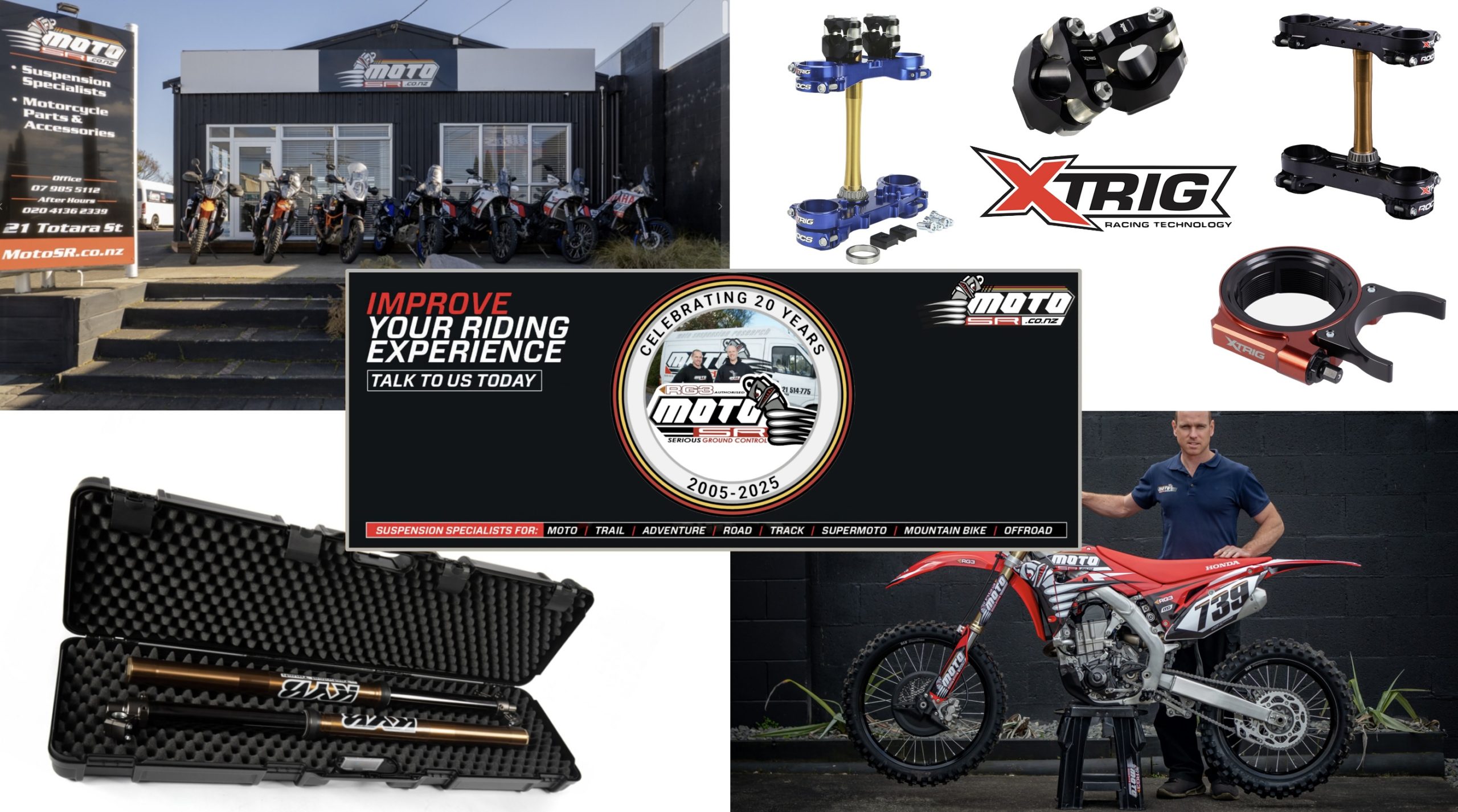

The Main Principles Of Motorcycle Parts New Zealand Specialists

Wiki Article

The Motorcycle Parts New Zealand Specialists Statements

Table of ContentsThe Motorcycle Parts New Zealand Specialists IdeasMotorcycle Parts New Zealand Specialists for DummiesMotorcycle Parts New Zealand Specialists Fundamentals ExplainedThe 45-Second Trick For Motorcycle Parts New Zealand SpecialistsSome Known Incorrect Statements About Motorcycle Parts New Zealand Specialists Motorcycle Parts New Zealand Specialists Things To Know Before You Get ThisThe 8-Minute Rule for Motorcycle Parts New Zealand SpecialistsMotorcycle Parts New Zealand Specialists Fundamentals Explained

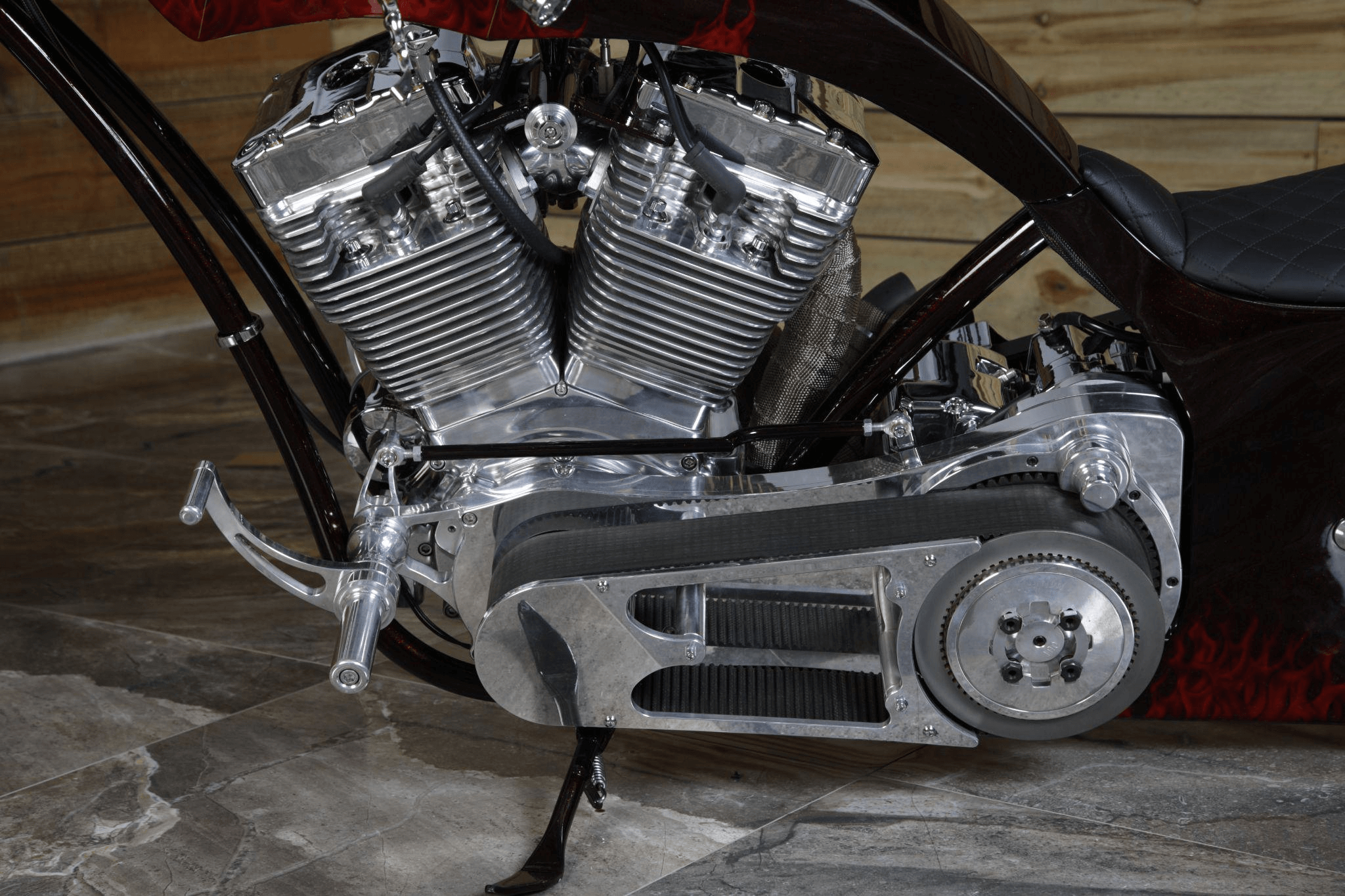

So, connect to among our specialists today.CNC machining modern technology is swiftly ending up being the centerpiece of several manufacturing procedures around the world as a direct outcome of its several benefits over various other approaches. In addition, the industries that make motorcycles have hopped on board with this fad. One of the most cutting-edge companies are now creating their engine parts and wheels making use of machining methods originally developed for motorbike parts.

You may be asking yourself why we make use of. Now that we have your focus allow us explain the rationale behind this modern-day development in the motorcycle production market.

Getting My Motorcycle Parts New Zealand Specialists To Work

In enhancement, you have total control over the look of the components, also down to the minute details. Periodically, motorcyclists may make a decision to spruce up their trip by setting up aftermarket components or customizing the bike's transformation.

Fascination About Motorcycle Parts New Zealand Specialists

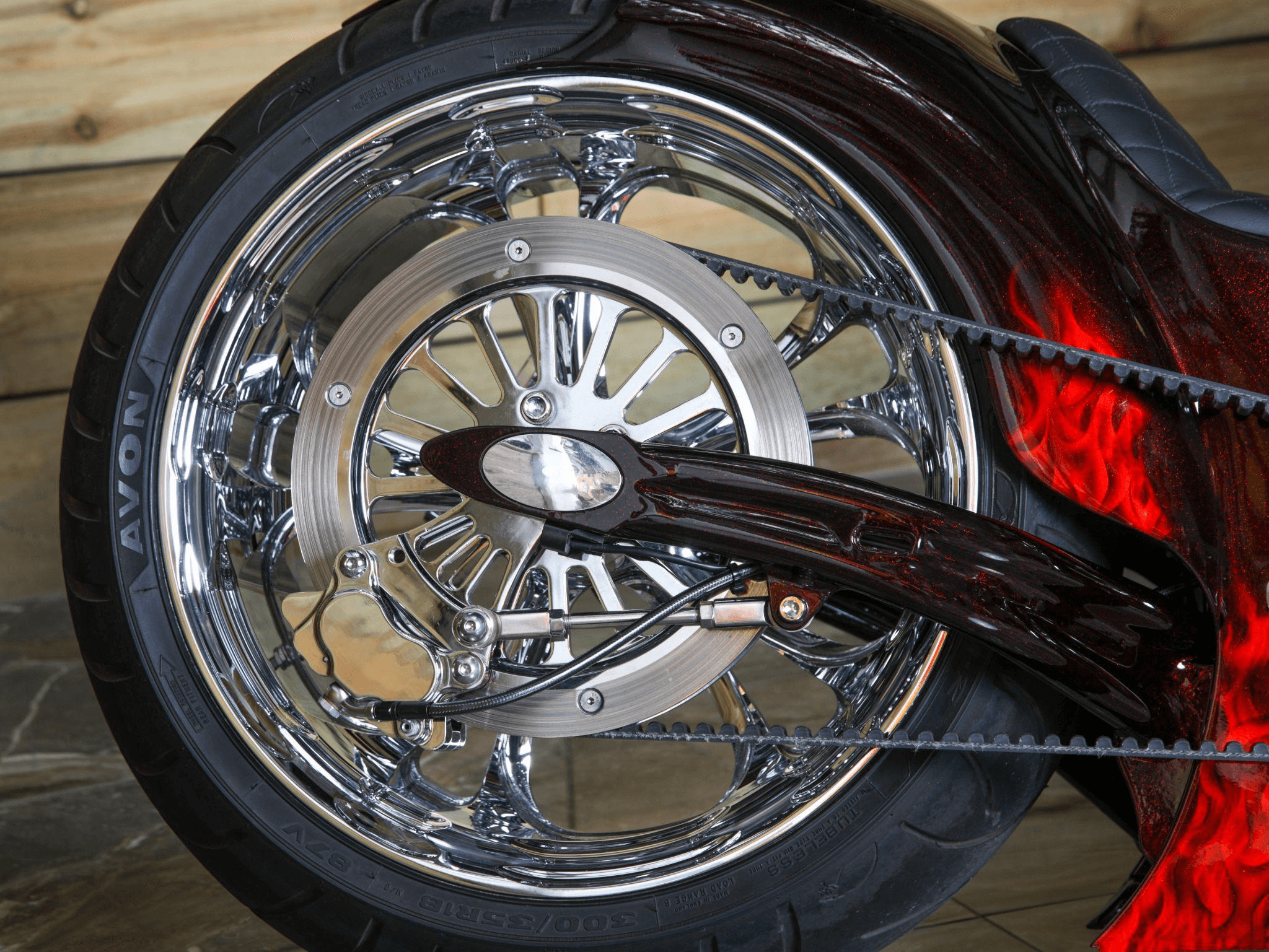

CNC machining may be utilized to make practically all of a bike's metal and plastic parts. To continue, we'll go over several machined components for bikes. Unlike those on cars, wheels on motorbikes tend to be extra evident. Therefore, the bike's appearances may be enhanced with the proper customization of these wheels.When personalizing the wheels, the disks are where the focus ought to be. The bulk of them are made out of light weight aluminum. Light weight aluminum alloys are popular for the outstanding machining capabilities that they have. Milling treatments are utilized to acquire the preferred degree of wheel customization. Another facet of the motorbike that may be personalized is the tires.

6 Easy Facts About Motorcycle Parts New Zealand Specialists Explained

When it comes to an automobile (or a motorbike), the most vital element is the engine. A number of people mention it as the "heart" of the automobile. On the various other hand, the camshaft, the cyndrical tube head, and the pistons have a tendency to be detailed and call for layouts with a high degree of precision.Usage just premium products, nonetheless, because these lights are essential for the safety of motorcyclists and various other chauffeurs or people on the road, especially at evening. Motorbike fronts lights have three major components: the bulb, or light source, the lens, and the real estate.

Milling procedures with a perfect finish would certainly result in the lenses having a reflective quality that resembles that of a mirror. The cover, on the other hand, is not composed of delicate products; rather, it is created out of tough polymers that can be machined into even more complex patterns.

Motorcycle Parts New Zealand Specialists Fundamentals Explained

They often have intricate geometries with a wealth of min details. Bike manufacturers commonly cast these components, however just for the production of bespoke parts. Nonetheless, CNC machining is the approach of choice when producing unique pieces. Machining on five axes in today's world is the ways through which any kind of design form may be recognized.Select Runsom for your personalized bike parts! We have the ability to produce challenging check and stylish parts making your motorcycle incomparable.

Below are a few instances of metals usually utilized in motorbike part machining. Aluminum is the primary product utilized by firms specializing in creating custom-made motorbike elements to produce many of these components - Motorcycle Parts New Zealand Specialists.

Zinc refers to an additional steel that is extremely light in weight and has wonderful machining qualities as a result of its high mechanical toughness. This product might be developed into practically any type of shape and maintains its dimensions well. Even mission-critical parts that need a high level of precision may take advantage of their use.

The Best Guide To Motorcycle Parts New Zealand Specialists

An additional metal that sees heavy use in the production of CNC-customized elements is magnesium. It is among the lightest steels that are now accessible and has superb machinability features and stamina appropriate with its reduced weight. One of the drawbacks of magnesium is that its dirt may conveniently capture fire.

Due to the fact that of its remarkable machinability and weldability, stainless steel is an alloy that is especially fit for CNC processes. They have great rust resistance and a high visual allure. Their most typical use in creating numerous bike parts is bolts, such as screws and screws. Their reduced susceptibility to oxidation and rust makes them suitable for this usage.

6 Easy Facts About Motorcycle Parts New Zealand Specialists Described

It appears that CNC turning and milling are the foundational procedures. Different techniques exist, such as drilling. Allow's examine a lot of these why not find out more machining strategies detailed. The CNC turning method is taken into consideration a subtractive manufacturing approach. Furthermore, it calls for keeping bars of material, most often plastic or metal, in position and after that twisting a cutting tool to remove areas of the product as the material is transformed.

These methods are similarly vital and create parts with high accuracy and constant quality. They are respectively: grinding, laser cutting, and boring. The term "surface area finish" refers to post-processes after the preliminary machining phase. Motorcycle Parts New Zealand Specialists. The processes assist boost the general top quality of the machined motorcycle components. Below are the short intro, advantages and disadvantages of 5 surface area therapy approaches.

Motorcycle Parts New Zealand Specialists Things To Know Before You Get This

Report this wiki page